Wood Heating Regulations – What You Need to Know in 2023

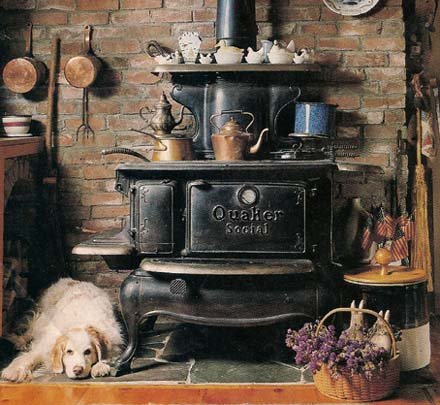

Wood heat is still the go-to heating solution for many Americans, and for good reason: It’s affordable, effective, and provides a comforting atmosphere with crackling, glowing flames in a firebox. The downside is that wood heat creates potentially dangerous emissions (soot and smoke), which are regulated by the Environmental Protection Agency. In recent years, regulations surrounding wood smoke have become stricter and more complex in order to keep up with a growing population and an increasingly varied market of wood heating devices, which has made it difficult for the average person to understand which rules apply to them and which do not. In this article, we aim to clear up any confusion so that your next wood heater purchase is hassle-free, whether it’s a wood stove, cook stove, or furnace.

Why Do We Have Emission Regulations?

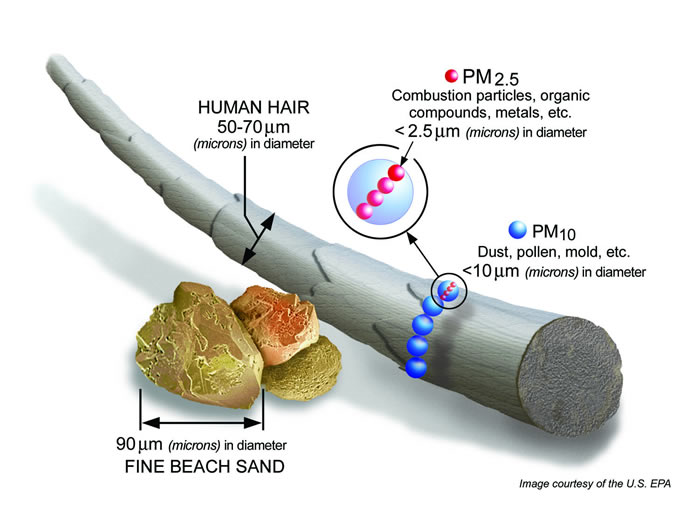

To fully understand why emission regulations exist, you have to know what particulate matter is. Particulate matter, often abbreviated as “PM”, refers to microscopic particles of solid or liquid matter suspended in the air. Particulate matter can be a variety of things: Dust, human hair, fly ash, smog, soot, and other substances that are small enough to be breathed in. When it comes to wood heat, however, there is one type of particulate that needs special attention: PM2.5.

When you burn wood, whether it’s a brush pile or a couple of logs in a cozy fireplace, the combustion of that wood releases a number of compounds. While you can see smoke with your naked eye and no doubt understand that it’s not good to breathe it in, you can’t see all the tiny harmful by-products of wood combustion: Carbon monoxide, volatile organic compounds (VOCs), and PM2.5. PM2.5 is fine particulate matter that measures less than 2.5 micrometers in diameter, making it small enough to be inhaled.

Inhaling PM2.5 can lead to conditions that range from mild inconveniences like burning eyes or a runny nose, to serious and potentially fatal incidents such as chronic lung disease, asthma attacks, and heart attacks. Simply put: PM2.5 can be very harmful to our health, and by using wood heat, we risk being exposed to it. So what can we do to safely take advantage of all the benefits of wood heating?

The answer is to make the combustion process as effective as possible, by designing efficient fireplaces, wood stoves, cook stoves, furnaces, and other heating units. It’s not possible to completely eliminate the particulates that wood combustion releases, but with modern stove technology, we can minimize how much is released to the point that it has minimal impact on our health. This is where the Environmental Protection Agency (EPA) steps in.

The EPA and You

The EPA established what’s called the “New Source Performance Standard” as part of the Clean Air Act in 1988 to set emission regulations for wood heaters. The need for these regulations, according to the EPA, arises from the fact that hundreds of thousands of wood heaters are in use across the United States, resulting in pollution that cannot be contained by county and state borders. While the EPA traditionally used the Clean Air Act to handle large-scale commercial or industrial facilities, the agency created a special certification program for residential wood heaters. This gave manufacturers the ability to certify an entire line of wood heater all at once through a single test, submitted by the manufacturer through an EPA-approved laboratory, instead of having the EPA inspect every single unit themselves which would have been far too costly for the many small businesses that make wood heaters.

In 2009, the EPA took another look at the state of wood heating and decided their regulations were out-of-date, given the advancement in heating technology since the 1980s, so they began a years-long review process. The review concluded in 2015, at which point the EPA released a revised set of emission regulations in an updated version of the New Source Performance Standard (you can read our in-depth analysis of where things stood in 2015 in our article here). These revised regulations aimed to reduce wood heat emissions by gradually phasing out the sale of lower efficiency (high emission) wood heaters.

EPA Emission Regulations For Wood Heaters Today

The following information is current as of 2023.

Before we dive into the details of emission regulations, it’s important to understand what this all means for you as a consumer. First and foremost is that if you already own a wood stove, cook stove, or any other wood heater that is not EPA certified, you don’t need to take any action. The EPA’s emission standards apply only to “newly manufactured adjustable-rate woodstoves, pellet stoves, wood-fired hydronic heaters, wood-burning forced-air furnaces, and a type of previously unregulated woodstove known as a ‘single burn rate’ stove.”

Furthermore, cook stoves are fully exempt from EPA emission standard if they meet the following criteria:

(1) An oven, with volume of 0.028 cubic meters (1 cubic foot) or greater, and an

oven rack;

(2) A device for measuring oven temperatures;

(3) A flame path that is routed around the oven;

(4) An ash pan;

(5) An ash clean-out door below the oven;

(6) The absence of a fan or heat channels to dissipate heat from the appliance;

(7) A cooking surface with an area measured in square inches or square feet that is at least 1.5 times greater than the volume of firebox measured in cubic inches or cubic

feet. Example: A cook stove with a firebox of 2 cubic feet must have a cooking surface of at least 3 square feet;

(8) A portion of at least four sides of the oven (which may include the bottom

and/or top) is exposed to the flame path during the heating cycle of the oven. A flue gas

bypass may exist for temperature control.

– Subpart AAA—Standards of Performance for New Residential Wood Heaters, § 60.531.

Fireplaces are also exempt if they meet the EPA’s criteria for what a fireplace is:

See the NSPS here for more details.

As a consumer of wood heat, it’s most important for you to understand your state and local air quality laws. Most states have emission limits that are equal to what the EPA has laid out (2.5 g/hr for wood heaters), but some states choose to provide additional restrictions or higher limits. The EPA provides a partial list of states with notable restrictions or requirements here.

What Do These Regulations Mean For The Sale and Manufacturing of Wood Heaters?

The EPA divides emission requirements for wood heaters into the following three categories:

| Heater Type | Emission Requirements |

| Woodstoves and Pellet Stoves | 2.0 grams per hour of PM, if tested with crib configuration. 2.5 grams per hour if tested with cordwood using an EPA-approved method of testing. |

| Hydronic Heaters | 0.10 pounds per million Btu heat output for each burn rate, 0.15 pounds per million Btu heat output if tested with cordwood using an EPA-approved method of testing. |

| Forced Air Furnaces | 0.15 pounds of PM per million Btu heat output for each individual burn rate (cordwood testing required). |

Regarding hydronic heaters and forced air furnaces: The emission standard does not apply to heating units that are fueled solely by gas, oil, or coal. It does apply to heaters or furnaces that can use both wood and other fuel sources.

Manufacturer Issues with Certification and Legal Challenges

There was some confusion amongst retailers and manufacturers as the industry transitioned from step one of the updated emissions (4.5g/hr after 5/15/2015) to step two (2.5g/hr after 5/15/2020). Now that we are several years beyond the effective date of the final emission standard as laid out in the revised NSPS, it’s worth looking at how the wood heat industry has reacted to the stricter requirements.

In 2021 the Hearth, Patio & Barbecue Association (HPBA), which represents manufacturers of residential wood heaters, filed a petition against the federal government claiming that the new audit process for wood heaters is invalid. As we mentioned earlier, in order for a wood heater to become EPA certified, one model in that heater’s production line has to be tested at an EPA-approved laboratory. The EPA created this process to help manufacturers avoid the costly and time-consuming alternative of testing every single heater individually.

To ensure that all certified stoves are in compliance and no errors were made in the certification process, the EPA occasionally selects a certified heater for an audit. From 1988 to 2015, those audits had to be performed by the same laboratory that certified the heater in the first place. In 2015, the EPA changed their guidelines to say that audits can be performed by any EPA-approved laboratory. In their petition, HPBA argued that this change was invalid because it does not account for how emissions testing varies from one laboratory to another. According to HPBA, this raises a serious problem for manufacturers: They could have a stove that is tested at one lab and meets the emission requirements, allowing it to gain certification and be put out on the market. But if the EPA later audits that stove and tests it at a different facility with results that do not meet the emission requirements, the manufacturer would lose their certification and the ability to sell an entire line of stoves, causing a level of profit loss than would endanger many of the small businesses that make wood heaters.

The EPA actually agrees with the HPBA that there is unavoidable variability in emissions testing, due to the fact that wood itself has natural variability in composition that affects how it burns. However, the HPBA argues that the EPA does not include any language in the revised NSPS that would allow some leeway for worse test results in an audit of an already certified stove, and by not including this, it renders the audit process invalid.

In response, the EPA pointed out that this situation had yet to occur because they had (as of 2021) not audited any heating devices under the 2015 rule, and in the event that a device did fail an audit, they would be willing to consider “any relevant information” from the manufacturer, including varied emission test results. The EPA also added more rigorous laboratory testing requirements starting in 2015 to increase the consistency of testing and introduced a margin of variability in the emission limits, meaning that a different emission test result in an audit would be less likely to lead to de-certification.

A federal appeals court ultimately sided with the EPA and denied the HPBA’s challenge in August of 2021, but it was not the last time the EPA’s wood heater regulations would be questioned.

In June of 2022, Minnesota-based wood furnace maker Lamppa Manufacturing attempted to renew the EPA certification on one of their lines of wood furnaces. The re-certification process does not require re-testing devices, and Lamppa had no reason to expect they would need to, yet that is precisely what the EPA asked them to do. Lamppa had already increased production on the wood furnace line in question, incurring production costs that they expected to cover with income from sales that fall. Unfortunately Lamppa’s existing certification was set to expire in September 2022, leaving them with an entire line of furnaces that could not be tested in time for re-certification, which meant they could not be sold. This fiasco cost Lamppa hundreds of thousands of dollars and nearly led to financial ruin, according to Daryl Lamppa, who oversaw wood furnace development at the company.

Adding insult to injury, Lamppa actually met the EPA emission standard of 0.15 pounds of PM per million BTUs in all four of their original test burns with that particular furnace line. Unbeknownst to Lamppa, though, was that the EPA had been unofficially requiring manufacturers to meet a limit of 0.14 pounds instead of 0.15. One of Lamppa’s four tests had an emission of 0.147, and the EPA used that single result to force Lamppa to re-test when they applied for renewed certification.

When interviewed by their local Minnesota newspaper, The Timberjay, Lamppa Manufacturing shed some light on the impracticality of the EPA’s testing procedures. It took Lamppa four months to schedule time at a certified testing lab after receiving their notice from the EPA to re-test, leaving the company unable to take orders for new furnaces as the sales season reached its peak, and another several weeks to complete the required four burns. As it turns out, the EPA had recently required testing labs to use a type of filter that was incompatible with wood furnaces, causing errors and forcing multiple restarts of the entire time-consuming testing process.

In the end, Lamppa was able to re-certify their wood furnaces with the EPA, but not until March 2023, when wood heater sales typically slow down as spring approaches. Lamppa Manufacturing are not the only ones to take issue with the EPA’s testing and certification process, though: Perhaps the most unexpected and vocal critic has been the Office of Inspector General, an independent office within the EPA that provides oversight of the agency.

In a February 2023 report, the OIG stated that “the EPA lacks internal controls to ensure that certification test reports are valid and that certification tests are conducted appropriately,” and that “certification tests may not be accurate, do not reflect real-world conditions, and may result in some wood heaters being certified for sale that emit too much particulate-matter pollution.”

The OIG also notes that the EPA has not responded to their recommendations for correcting these issues, and mentioned that “state regulators told us that they cannot rely on the EPA’s certifications of wood heaters and, therefore, develop their own standards and lists of approved wood heaters for sale.”

As of this writing, the EPA has still not responded to the OIG report, but Lamppa Manufacturing told The Timberjay that after the report was released, the agency began to implement some of the changes to the testing process that they recommended. Whether this is a sign of more improvements down the road remains to be seen, but it’s clear that the process for acquiring EPA certification on a wood heater is one that needs improvement.

Summary

For consumers, the time has never been better to invest in wood heat. There are a multitude of clean burning wood heaters available in the form of furnaces, boilers, stoves, cook stoves, and fireplaces, many of which have been adequately tested and are truly efficient. The industry has come a long way since the EPA began monitoring PM emissions in the United States in 2000, with improved manufacturing and leaps in heating technology leading to a steady decline in national PM2.5 levels over the last twenty years. For those who rely on wood heat, or simply enjoy the ambiance of a cozy fire, wood heating is as good as it’s ever been. The way we make sure our heat is clean and efficient is, unfortunately, still a work in progress, with needless frustration for manufacturers. Things may be improving recently, but only time will tell if the EPA has sincerely listened to the the expertise of manufacturers when it comes to improving the certification process.

Resources

FACT SHEET: Summary of Requirements for Woodstoves and Pellet Stoves

FACT SHEET: Summary of Requirements for Wood-fired Hydronic Heaters

FACT SHEET: Summary of Requirements for Wood-fired Forced Air Furnaces

EPA Ordinances and Regulations for Wood-Burning Appliances

EPA Regulatory Actions for Residential Wood Heaters

EPA-Approved Test Labs and Third-Party Certifiers for Residential Wood Heaters

EPA Compliance Requirements for Residential Wood Heaters

Heatmaster: How 2020 EPA Emissions Laws Affect Your Outdoor Furnace

Reuters: Court denies challenge to wood-fired residential heater test standards

The Timberjay: Investigation raps EPA’s wood burner testing

Report: The EPA’s Residential Wood Heater Program Does Not Provide Reasonable Assurance that Heaters Are Properly Tested and Certified Before Reaching Consumers